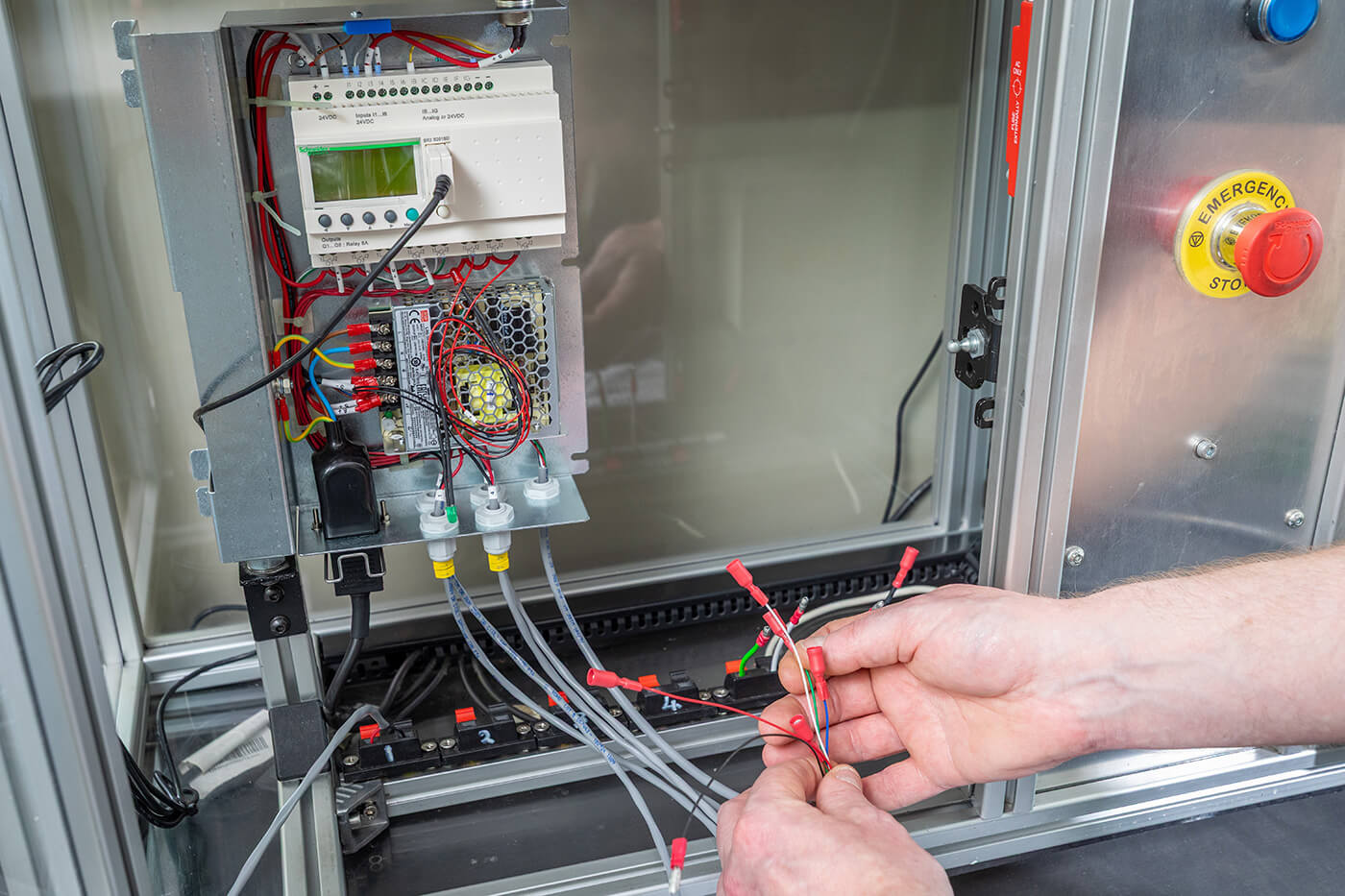

Scalable, Automated Solutions

Significant investment in automation and semi-automated technologies is at the core of our manufacturing strategy. Our capital investments are critical to achieving high-throughput production, reducing variation and ensuring consistent quality across all cable assembly builds. This proactive approach allows us to offer scalable, cost-efficient solutions without compromising performance or reliability

Komax Alpha Multifunction Crimp Centre

Our latest investment from Komax, the multi station fully-automatic wire cutting, processing and crimping technology, has further strengthened our already strong line up of wire and cable processing equipment to ensure we maintain the very high levels of service and quality our customers demand.

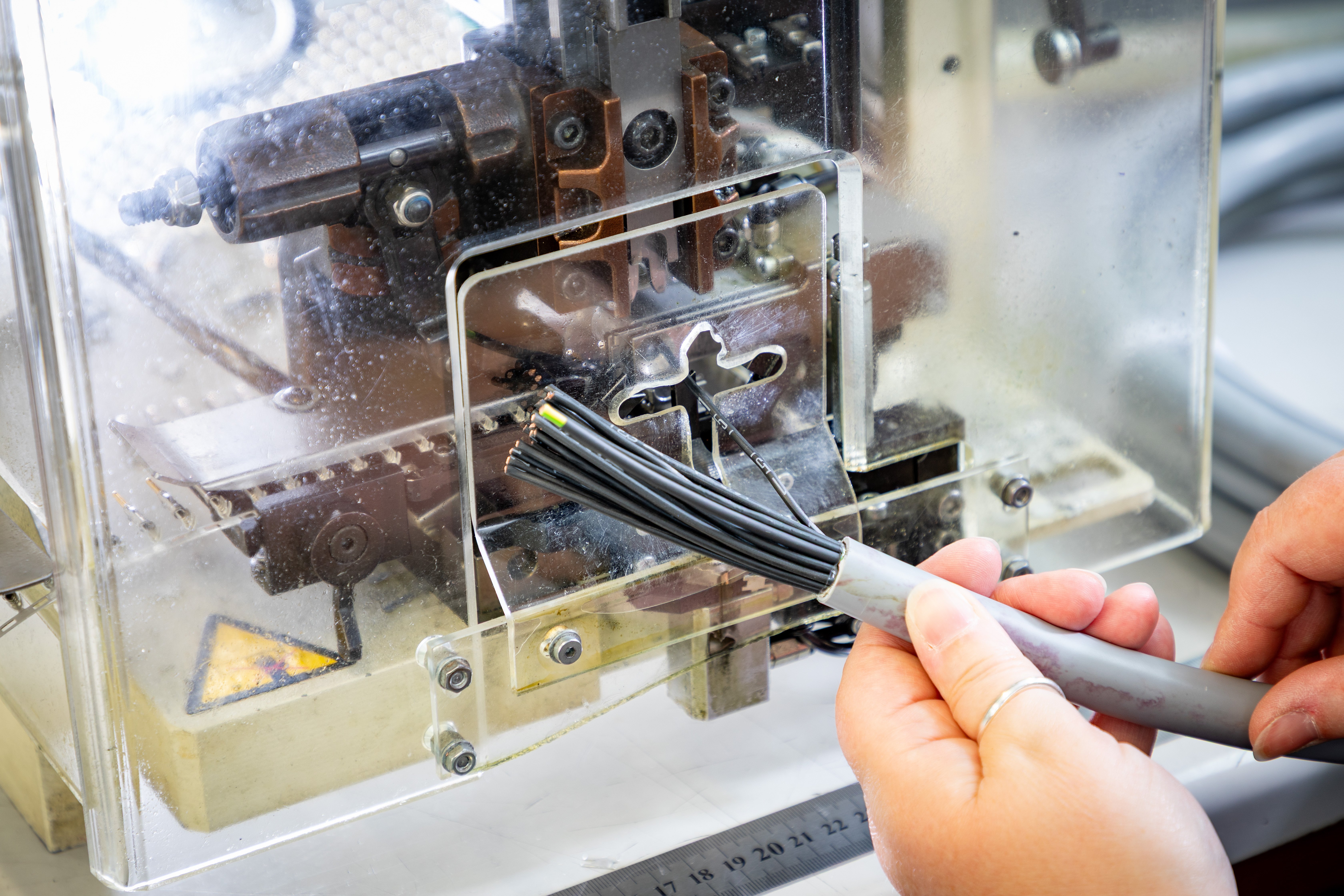

Komax Mira Power Stripper

Employing the latest generation technology this power stripper from Komax enables cutting and stripping of multi-core power and data cables including precision stripping of inner cores.

Schleuniger CrimpCentre 36: Fully-automatic wire cutting, processing, tin dip and crimping technology from Schleuniger

Co-axial Stripper: Programmable rotary cutting of co-axial and tri-axial cables up to 11mm OD and strip lengths up to 40mm.

Unistrip 2300: The UniStrip 2300 programmable stripping machine strips wires ranging in size from 0.03 – 8 mm² (32 – 8 AWG) and jacketed cables up to 5.5 mm (0.22″) in diameter. The machine features a smart detect option for quality assurance.

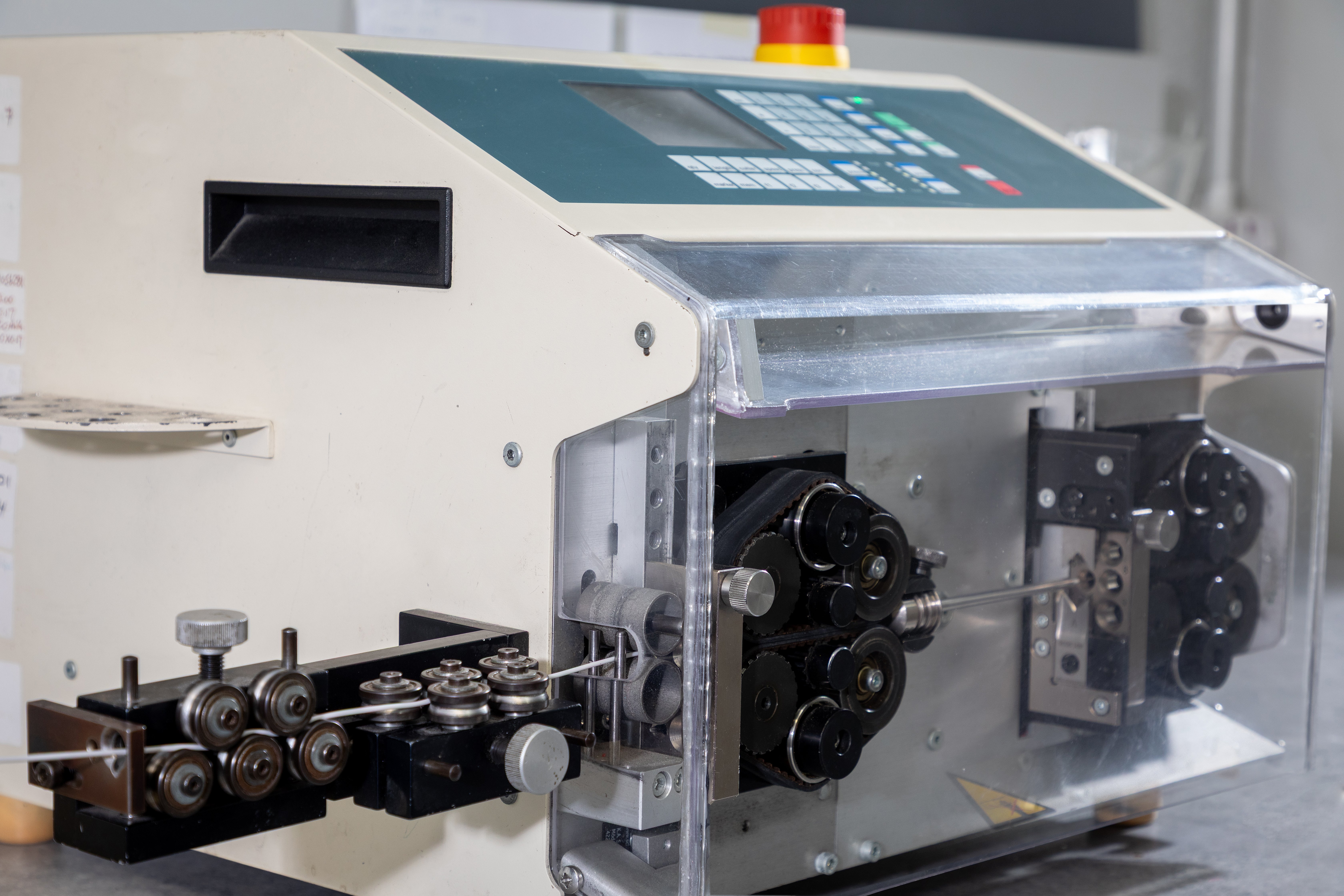

Cable Cutting Machines

Eight automated wire-cutting machines enable the processing of a vast array of single core wire, copper braid and multi-core cables together with all types of sleeving. Equipment from Kodera, Komax and Schleuniger combines precision and consistent stripping quality with high-speed processing.

-Wire range: single core wires from 0.03mm² to 10mm² (32AWG – 8AWG)-Hydraulic cutting: up to 120mm²

-Ribbon cable, sleeving and heat shrink up to 130mm width

Crimp Terminal Press

Support for all leading terminal manufacturers with a wide range of automatic tooling, including mini applicators from AMP, Molex, JST, Harwin, Cembre etc, fixed die automatic presses for pre-insulated terminals, heavy duty pneumatic presses (up to 4mm²) and heavy duty hydraulic presses (up to 120mm²).

Heat Shrink Ident Printer

Flag Labeller

We offer wire identification and our sister division Weyfringe Barcode & Labelling Systems can also supply you with your own cable ident system allowing you to print as many cable idents as you need.

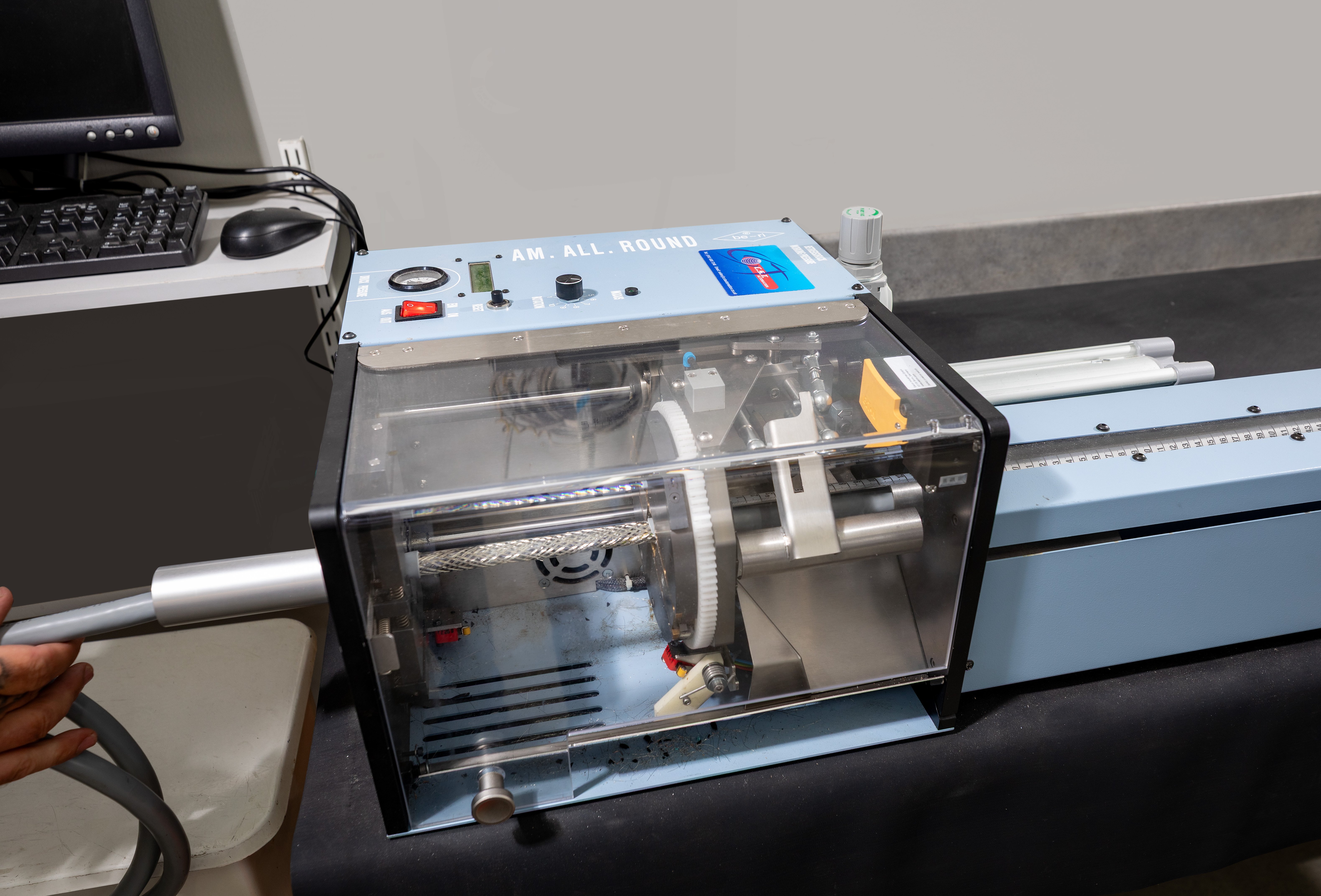

AM All Round Stripper

Arrange a factory visit

Why not arrange to visit our factory and see for yourself our cable assembly manufacturing capabilities in real time? One of our engineers will be happy to provide a guided tour and answer any questions about our manufacturing processes.