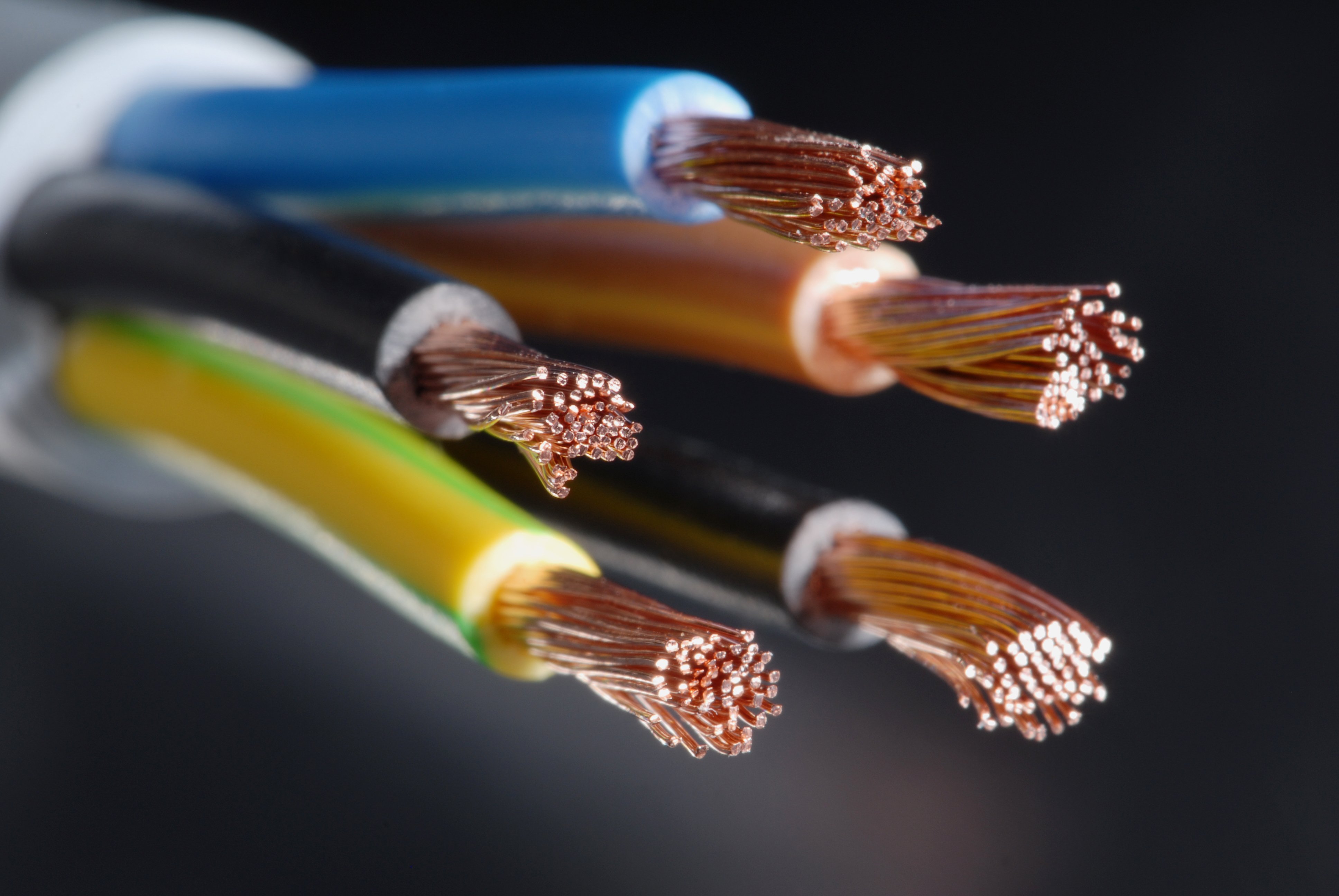

Cut & Prepared Wires

From simple cut-and-stripped wire lengths to fully terminated wires with crimped or tinned ends, Connect-2 Technology can deliver prepared wiring for integration into your assemblies, panels or systems. We can also supply flexible braid and earth strap assemblies manufactured to individual customer specifications. We can provide a wide range of termination options to ensure you achieve the relevant bond between your anchor point and the conductor.

Connect with us

Capabilities

We offer scalable wire processing with a range of end-preparation options, including

- Precision wire cutting

- Automated stripping of single core or multicore cables

- Tinned ends - hot dip or precision tinning

- Crimp terminations with insulted/uninsulated terminals (ring, fork, spade, bullet etc)

- Flexible braid and earth strap preparation

Each process is performed using calibrated tooling to ensure consistent electrical and mechanical performance. We strictly follow OEM specifications for terminations to guarantee proper contact resistance, pull off force, and fit within the intending housing or terminal block.